IGBT has long relied on foreign giants for a "core" in the new energy industry

In 2018, new energy vehicles have maintained relatively high speed development. On December 10, the China Passenger Car Market Information Association (hereinafter referred to as "the Association") released the production and sales data of Chinese passenger cars in November. In November, the wholesale sales of new energy vehicles reached 136,000 units, with a month-on-month growth of 19.1% and a year-on-year growth of 69%; The plug-in hybrid ratio increased by 87 percent, and the pure electric ratio increased by 65 percent year-on-year. From January to November, 880,000 new energy passenger vehicles were wholesale.

However, at the same time of the rapid development of new energy vehicles, the lack of production capacity of its upstream parts is easy to cause "congestion". Chen Gang, general manager of BYD's sixth Division and solar division, said that in terms of production capacity, the development of new energy vehicles will be limited by the current production capacity of batteries and IGBT products.

Relevant data show that China's IGBT market has been monopolized by international giants, with 90% share in the hands of overseas giants such as Infineon and Mitsubishi. Zhou Shengming, deputy director general of IC Design Branch of China Semiconductor Industry Association, said that the largest single product import in China is chips, enterprises have dependence on foreign products, but this dependence is not desirable, especially when the product competition.

Automobile enterprises "spend money" to develop IGBT

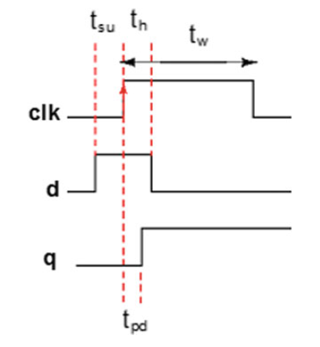

It is understood that IGBT (Insulated Gate Bipolar Transistor, insulated gate bipolar transistor) is a high-power power electronic device, mainly used in frequency converter inverter and other inverter circuits, inverter DC voltage into alternating current with adjustable frequency, commonly known as the "CPU" of power electronic devices. IGBT is the core device of energy conversion and transmission. Using IGBT for power conversion can improve the efficiency and quality of electricity consumption, which is the key technology to solve the problem of energy shortage and reduce carbon emissions.

On December 10, BYD Co. LTD. (002594.SZ, hereinafter referred to as "BYD") released IGBT4.0 technology. In the afternoon of the same day, China Business News reporters went to Ningbo BYD Semiconductor Co., LTD., visited the IGBT manufacturing in four important areas: diffusion area, thin film area, yellow light area and etching area. Wu Haiping, senior research and development manager of BYD's sixth Division, introduced the IGBT4.0 current output capacity is 15% higher than the current market mainstream IGBT; Under the same conditions, the IGBT4.0 loss is reduced by about 20% compared with the current mainstream IGBT in the market.

Regarding BYD's development in IGBT, Chen Gang said that BYD set up an IGBT research and development team in 2005 and acquired the Ningbo Zhongwei Semiconductor Wafer Factory in October 2008. "Currently, BYD is the only automaker in China with a complete industrial chain: IGBT chip design and manufacturing, module design and manufacturing, high-power device testing and application platform, power supply and electronic control, etc."

In addition, BYD has invested heavily in the deployment of SiC(silicon carbide), a third-generation semiconductor material with better performance, and is expected to launch an electric vehicle with SiC electric control in 2019, Chen said. Byd's electric vehicles are expected to be equipped with SiC electric control by 2023.

It is understood that in the domestic market, only CRRC Times Electric, BYD and other enterprises master the research and development of IGBT production. In the past two years, SAIC, Beiqi and other vehicle enterprises began to master relevant technologies through cooperation with other enterprises.

The international giants have serious monopolies

As one of the mainstream new power electronic devices, IGBT is widely used in rail transit, smart power grid, aerospace, electric vehicles, new energy equipment, as well as industrial fields (AC/DC electric conversion and frequency conversion control in high-voltage and high-current occasions), and is the core technology of the above applications.

However, statistics show that the IGBT market in China has been monopolized by international giants, with 90 percent of the share in the hands of overseas giants such as Infineon and Mitsubishi. Zhou Shengming said that the largest single product import in China is chips, so there is a dependence on foreign products, but this dependence is not desirable, especially when the products form competition.

China's domestic IGBT market was worth about 12.1 billion yuan in 2017, accounting for about 50 percent of the global total demand, according to research by CITIC Construction Investment. However, Chinese IGBT started late, the domestic market share is mainly monopolized by international giants, the localization rate is only 11%, the import dependence degree is high, the domestic substitution space is huge.

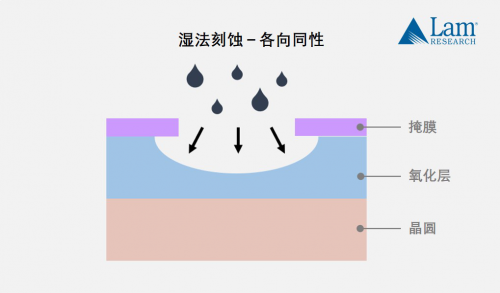

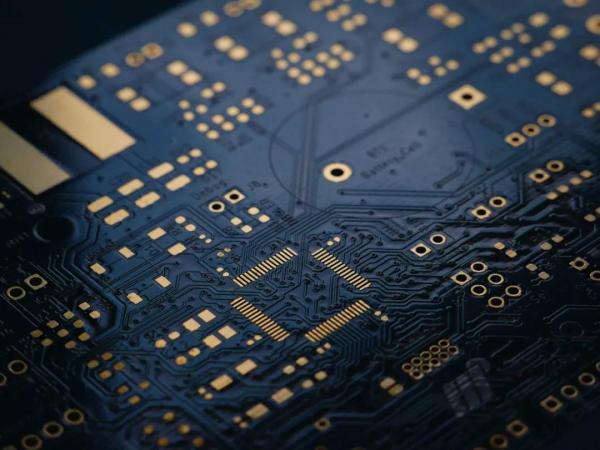

Domestic research and development of IGBT enterprises less, or with IGBT research and development and production of high difficulty. Byd technicians said that the IGBT chip is only the size of a human fingernail, but it needs to etch tens of thousands or even hundreds of thousands of microstructural circuits on it, which can only be viewed under a microscope.

From the IGBT chip design, involved in more than a dozen parameters, many of the parameters are contradictory, need to consider the compromise according to the application. In terms of wafer fabrication, IGBT, which uses the latest 1200V FS technology, requires wafer thinning to 120um(about the diameter of two human hair strands) and more than 10 processes. "Wafer manufacturing facilities are very clean and require a first level of purification. A tiny fraction of a micron of dust falling on a wafer can cause an IGBT chip to fail." The above technician said.

In addition, IGBT module design is also very difficult, need to consider material matching, heat dissipation, structure, power density, appearance, weight and other indicators.

Chen Gang said that the semiconductor research and development threshold is high, not only rely on capital can do well, research and development process also needs downstream pull. "If the upstream and downstream do not have good communication and integration, the products that may cost a huge amount of money are not suitable for the application side, resulting in the possibility of disconnection with the downstream." Yang Qinyao, product director of BYD's sixth Division, also told reporters that application pulling, talent training and product standardization are three elements in IGBT production.

Take on the IGBT market

In 2018, the production and sales of new energy vehicles have exploded. From 2018 to 2020, the annual compound growth rate of China's new energy vehicle output will exceed 40%, and the output of China's new energy vehicle is expected to reach 1 million units in 2018.

The rapid development of new energy vehicles may drive the growth of the IGBT market. IGBT and batteries are the two core technologies that restrict the development of electric vehicles today, while chips are the core industry of modern manufacturing, Chen said. It is reported that IGBT, as the core parts of new energy vehicles, accounts for about 5% of the total vehicle cost.

According to Jibang Consulting, the IGBT market driven by China's new energy vehicles and related industries will total more than 120 billion yuan between 2018 and 2025. Among them, in 2025, China's new energy vehicle IGBT market scale will reach 21 billion yuan; From 2018 to 2025, the cumulative new market size of IGBT used in China's new energy vehicles exceeded 90 billion yuan.

But at the same time, the growth rate of new energy vehicles or significantly higher than the vehicle gauge IGBT growth rate, resulting in increasingly tight IGBT supply. From the current situation, according to the statistics of IGBT product delivery cycle in the first half of 2018 by Fuchang Electronics LTD (one of the world's three major electronic components distributors), IGBT delivery cycle has been significantly extended, and will be extended in the Future period of time.

Statistics show that, generally speaking, the IGBT delivery cycle is about 8 to 12 weeks, but in the fourth quarter of 2017, most manufacturers have extended the delivery cycle to 18 to 20 weeks. In the first half of 2018, the average lead time has been extended to 20 to 26 weeks, and the maximum lead time for IGBT modules used in automobiles is 52 weeks. Major suppliers of IGBT products such as Infineon, ON Semi and IXYS are all experiencing extended lead times.

Sinolink Securities said annual global new-energy vehicle sales are expected to reach 6 million units in 2022, with a compound annual growth rate of 30 percent from 2018 to 2022. However, the CAGR of the IGBT market was only 15.7% during the same period.

快发智造

快发智造