How far has China come to catch up with semiconductors?

Semiconductors are used in everything from smartphones and medical devices to defense and military industries. Today, the semiconductor industry has become a battle of national strategies, and the struggle for dominance in the semiconductor industry is morphing into a 19th-century clash between rival powers for control of Central Asia. It is just that the modern game is now largely about increasing industrial capacity and developing the latest technology.

Although, under the current global industrial chain and supply chain system, especially in the smartphone market, China has formed a complete industrial chain of electronic products manufacturing. But for three categories of companies in the semiconductor industry, the Chinese play the role of rule follower. Where is China's semiconductor catch-up now, given the continuing US technology blockade?

American monopoly

The semiconductor industry chain has many links, a high degree of professional division of labor, and the innovation and application of technology is an important driving force of the industry. Specifically, the upstream and downstream of the semiconductor industry chain includes three major links: IC design, wafer manufacturing and processing, packaging and testing, and application.

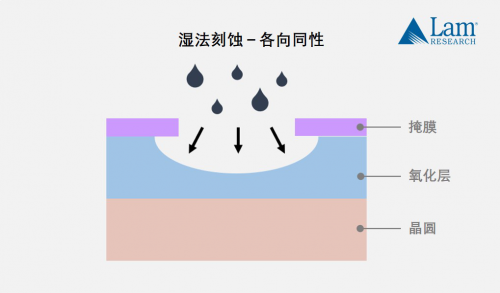

Among them, IC design refers to the selection and combination from the system, module, circuit and other levels according to the needs of the end product, determine the structure of the device, process plan, etc., to achieve the relevant function and performance requirements, and entrust it to the wafer foundry for production and processing; Wafer manufacturing plant makes mask to form template according to the design layout, manufactures integrated circuits in batches on the wafer, and finally transplants the circuit diagram designed by IC design company onto the wafer through repeated application of doping, deposition, phottography and other processes. The finished wafers are then sent to the downstream sealed test plant for cutting, welding, and plastic sealing to prevent physical damage or chemical corrosion, and at the same time to achieve electrical connection between the chip circuit and external components, and finally handed over to the downstream manufacturer.

At present, the semiconductor industry chain is actually a monopoly mode led by the United States. The U.S. semiconductor industry accounts for almost half of the global market share, although it suffered significant losses in global market share during the 1980s. In the early 1980s, U.S.-based manufacturers accounted for more than 50 percent of global semiconductor sales. But due to intense competition from Japanese companies, the effects of illegal "dumping" and a severe industry recession in 1985-1986, the U.S. semiconductor industry lost 19 market shares worldwide and lost its global market share leadership to Japan.

But over the next decade, the U.S. semiconductor industry rebounded, and by 1997 it regained its leadership position with a global market share of more than 50 percent, a position it has held to this day. American semiconductor companies maintained a competitive edge in microprocessors and other leading devices, and continued to lead in other product areas. In addition, American semiconductor companies remain leaders in research and development, design and process technology.

According to the SIA 2020Factbook report, US companies had the largest market share of 47% in 2019. Industries from other countries or regions have between 5% and 19% of the global market; Us semiconductor companies account for about 81% of total semiconductor wafer manufacturing capacity; In addition, semiconductor companies in the Asia-Pacific region account for most of the remaining U.S. production, about 10 percent. About 44 percent of U.S. companies' front-end semiconductor wafer production is located in the United States, followed by Singapore, Taiwan, Europe and Japan.

Of course, the global leadership of the U.S. semiconductor industry is contingent on technological breakthroughs and product innovations resulting from massive R&D investments. Semiconductors are highly complex products produced by highly advanced manufacturing processes, and these breakthroughs require huge and sustained investment of capital and talent over many years. The U.S. semiconductor industry has always focused on research and development, and high investment has led to technological leadership, which has allowed U.S. companies to establish a virtuous cycle of innovation.

After all, annual US R&D spending (as a percentage of sales) has exceeded 10 per cent for the past 20 years. This rate is unprecedented in major manufacturing sectors of the U.S. economy. According to the 2019 EU Industrial R&D Investment League table, the US semiconductor industry is second only to the US pharmaceutical and biotechnology sectors in terms of R&D spending as a percentage of sales. Clearly, R&D spending is critical to the competitive position of semiconductor companies, and the rapid pace of technological change also requires continuous progress in process technology and equipment capabilities.

The resulting US monopoly in the global semiconductor industry is obvious. The US not only has a monopoly on core technologies, but also controls the global industrial chain. When the United States and its partner countries put some key materials and production equipment on the control list, the safety of our semiconductor industry and related industrial systems was naturally endangered.

快发智造

快发智造